|

|

|

oxygen sensor 2006 cobalt

|

|

|

|  |

|

Zephex

Novice

Oct 27, 2014, 5:30 AM

Post #1 of 10

(8313 views)

|

oxygen sensor 2006 cobalt

oxygen sensor 2006 cobalt

|

Sign In

|

|

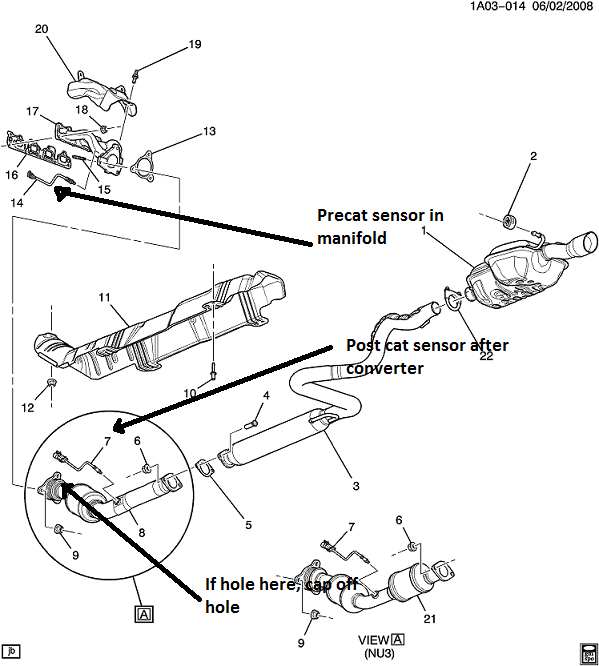

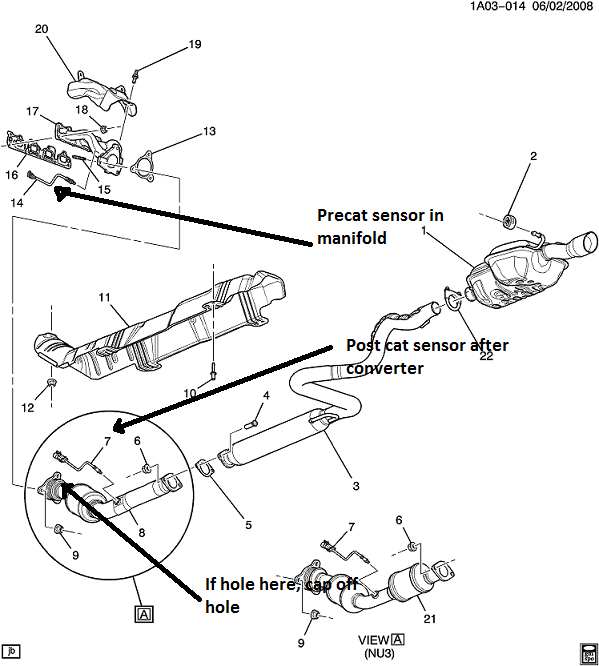

I had to replace the catalytic converter on my 2006 Chevrolet Cobalt. It is the LS version not the SS version.

when I took off the old converter, the oxygen sensor was behind the converter. It was between the converter and the exhaust pipe. New converter I installed has 2 holes for sensors. One in the same place as the old one, and then one before the actual converter up near the flex pipe.

the converter installed fine. But I think we may have damaged the o2 sensor during changing. The check engine light came on a few hours after replacing the converter. I looked online for a new sensor and everything I have found shows that the sensor goes into the hole before the converter. If this was the case, why was the o2 sensor after the converter on the original one we replaced?

I guess what I am asking is where does the o2 sensor on my car truly belong? Does it go before the converter or after it? I can plug the other hole using a spark plug or something like that. I just find it odd that the original o2 sensor was behind the converter but everything that I find online shows that it goes before the converter.

I am NOT a mechanic and I am just learning how to work on cars so any help will be appreciated

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Oct 27, 2014, 6:01 AM

Post #2 of 10

(8304 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

? Why did you install a part that wasn't the same or exact at all? What was wrong to begin with as it's too early for a converter IMO unless damaged.

Also what did you do with the other extra hole? If your old O2 sensor fit in fine and same code or one for that sensor BEHIND converter and it still runs well you probably did harm the other.

There's another before the converter somewhere but may not be right there. Generic and aftermarket parts it sounds like are not good for this stuff IMO.

If it runs well and only code for that sensor BEHIND converter you probably didn't need it yet but can't know that,

T

|

|

|  |

|

Zephex

Novice

Oct 27, 2014, 6:11 AM

Post #3 of 10

(8300 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

the original converter was cracked up by the flex pipe and it was making it very loud. I bought a replacement part off the internet that was compatible with my car. It fits perfectly and has no issues. The only difference between the original one and the new one is that the new one has holes for two sensors were the original only had holes for one.

when I took the o2 sensor out of the old one which was behind the converter. I put the o2 sensor in the same place on the new one. As for the extra hole all I did was plug it up using a spark plug that fit perfectly. Its only purpose is to seal the hole. My car only uses one sensor. That is why I'm assuming I may have damaged it when I was changing converters. It is not a problem to buy a new one but like I said, it looks like the o2 sensor should be installed in front of the converter. But this wasn't the case on the old one that I took out.

|

|

|  |

|

Zephex

Novice

Oct 27, 2014, 6:14 AM

Post #4 of 10

(8297 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

the reason I'm saying it should be installed before the converter is because most of the replacement parts that I find online when searching for an oxygen sensor for my car shows it going before the converter. With a very short wire

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Oct 27, 2014, 6:24 AM

Post #5 of 10

(8295 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

OK - There's an unpstream O2 sensor somewhere BEFORE converter listed - just looked. That one or two if two as I need engine size to find the exact layout does matter on how it runs. Downstream sensor is taking note if exhaust is in fact all set AFTER the converter but doesn't change settings for how engine runs like fuel mix and more.

Plugging hose not needed is fine. You really should get some real code readings and can test some O2 sensors and the wires that go to them are trouble too but codes will not say what is wrong just a circuit showing the fault.

This aftermarket junk may not even be working properly already - can't know. Converters are expensive and more expensive to get the OE ones. Apparently the connectors are popular for this car and may not need a sensor at all. Shows one of a couple possible.........

^^ Pic may not show?

Get much better code reading and a diagnosis of where the problem is right now,

T

|

|

|  |

|

Zephex

Novice

Oct 27, 2014, 6:30 AM

Post #6 of 10

(8289 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

ok, that makes some sense then. I would not have had to touch the upstream sensor to take the old converter out if it is not on the converter itself. So really the only thing that can be throwing the engine light would be us damaging the o2 sensor when we took it out, or the converter is just a piece of crap. I have ordered something to let me read the codes on the car. I didn't have anything like that but it is on the way now. Hopefully it will shed a little light on the situation.

will the code tell me if the sensor is bad or not? How will I know if it is the sensor or the converter itself?

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Oct 27, 2014, 6:54 AM

Post #7 of 10

(8285 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

Give me/us some info please! What engine! Forget owning your own code reader as this should be a free read for just this at many parts outlets should say which sensor has the problem if not find one that will.

Pre converter is critical at how the engine runs as said and make adjustments to how engine runs so it's both clean and fuel efficient with the most performance.

I worry about aftermarket or worse internet shopping for much of anything and converters have plain expensive metals used so room for some cheating a little or a lot which is why OE is suggested even at the choking costs.

At least do a visual on all wires and connections again if not already. Long done with this stuff unless I have to but one of my own has four and the dang wires going into sensors were rusting the cap ends off the sensors so did them all for that not that they didn't work otherwise.

If you needed to use heat to remove old sensor it no doubt killed it,

T

|

|

|  |

|

Zephex

Novice

Oct 27, 2014, 7:02 AM

Post #8 of 10

(8279 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

engine is the 2.4 version. The LS model car.

we did not have to use heat to remove the old sensor but it was hard to get out.it took a lot of work but it finally came out without stripping anything. I don'T no what kind of force it takes to damage a sensor. I don't know if breaking loose from the old converter could have damaged it or not. Below is a link to the converter that I bought for my car.

link deleted ............. not allowed

(This post was edited by Hammer Time on Oct 27, 2014, 7:27 AM)

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Oct 27, 2014, 7:21 AM

Post #9 of 10

(8277 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

I guessed at that engine size. OK - you can test your sensor but beware - put protective underwear on so when/if you sh*t yourself as to how you'll see why you should really get a diagnosis and pay for it. New sensor is about $55 bucks for cheapo AYOR all along. The converter you have may or may not be working? Can't know that from here.

This is what I found published on checking an O2 sensor and equipment required. Do rule out stupid wires first and if you lubed up the thing with all the wrong stuff into new converter it may be the problem too. Tough call.

Have run reading if this shows.............

***********************

ZTest/Replace

Oxygen sensors produce a voltage based on the amount of oxygen in the exhaust. Large amounts of oxygen result from lean mixtures and result in low voltage output from the O2 sensor. Rich mixtures release lower amounts of oxygen into the exhaust, therefore, the O2 sensor voltage is high. The engine must be at normal operating temperature before the oxygen sensor is tested. Always refer to the specifications supplied by the manufacturer.

Before testing an O2 sensor, refer to the correct wiring diagram to identify the terminals at the sensor. Most late-model engines use heated oxygen sensors (HO2S). These sensors have an internal heater that helps to stabilize the output signals. Most heated oxygen sensors have four wires connected to them. Two are for the heater and the other two are for the sensor. Use a wiring diagram to identify the terminals on a heated oxygen sensor. Courtesy of American Honda Motor Co., Inc.WARNING An oxygen sensor must be tested with a digital voltmeter. If an analog meter is used for this purpose, the sensor may be damaged. Use a wiring diagram to identify the terminals on a heated oxygen sensor. Courtesy of American Honda Motor Co., Inc.WARNING An oxygen sensor must be tested with a digital voltmeter. If an analog meter is used for this purpose, the sensor may be damaged.

Testing With A Digital Mulitmeter - Connect the voltmeter between the O2 sensor wire and ground.

- Backprobe the connector near the O2 sensor to connect the voltmeter to the sensor signal wire. If possible, avoid probing through the insulation to connect a meter to the wire.

- With the engine idling, the sensor voltage should be cycling from low voltage to high voltage. The signal from most O2 sensors varies between 0 and 1 volt.

- If the voltage is continually high, the air/fuel ratio may be rich or the sensor may be contaminated by RTV sealant, antifreeze, or lead from leaded gasoline.

- When the O2 sensor voltage is continually low, the air/fuel ratio may be lean, the sensor may be defective, or the wire between the sensor and the computer may have a high-resistance problem.

- If the O2 sensor voltage signal remains in a mid-range position, the computer may be in open loop or the sensor may be defective.

- The sensor can also be tested after it is removed from the exhaust manifold.

- Connect the voltmeter between the sensor wire and the case of the sensor.

- Using a propane torch, heat the sensor element. The propane flame keeps the oxygen in the air away from the sensor element, causing the sensor to produce voltage.

- While the sensor element is in the flame, the voltage should be nearly 1 volt.

- The voltage should drop to zero immediately when the flame is removed from the sensor.

- If the sensor does not produce the specified voltage or if the sensor does not quickly respond to the change, it should be replaced.

- If a defect in the O2 sensor signal wire is suspected, backprobe the sensor signal wire at the computer and connect a digital voltmeter from the signal wire to ground with the engine idling.

- The difference between the voltage readings at the sensor and at the computer should not exceed the vehicle manufacturer's specifications. A typical specification for voltage drop across the average sensor wire is 0.02 volt.

- Now check the sensor's ground.

- With the engine idling, connect the voltmeter from the sensor case to the sensor ground wire on the computer. Typically, the maximum allowable voltage drop across the sensor ground circuit is 0.02 volt.

- Always use the vehicle manufacturer's specifications. If the voltage drop across the sensor ground exceeds specifications, repair the ground wire or the sensor ground in the exhaust manifold.

- Most late-model engines are fitted with heated O2 sensors.

- If the O2 sensor heater is not working, the sensor warm-up time is extended and the computer stays in open loop longer. In this mode, the computer supplies a richer air/fuel ratio. As a result, the engine's emissions are high and its fuel economy is reduced.

- To test the heater circuit, disconnect the O2 sensor connector and connect a voltmeter between the heater voltage supply wire and ground.

- With the ignition switch on, 12 volts should be supplied on this wire. If the voltage is less than 12 volts, repair the fuse in this voltage supply wire or the wire itself.

- With the O2 sensor wire disconnected, connect an ohmmeter across the heater terminals in the sensor connector.

- If the heater does not have the specified resistance, replace the sensor.

Testing With A Scanner

The output from an O2 sensor should constantly cycle between high and low voltages as the engine is running in closed loop. This cycling is the result of the computer constantly correcting the air/fuel ratio in response to the feedback from the O2 sensor.

When the O2 sensor reads lean, the computer will enrich the mixture. When the O2 sensor reads rich, the computer will lean the mixture. When the computer does this, it is in control of the air/fuel mixture. Many things can occur to take that control away from the computer. One of them is a faulty O2 sensor.- The activity of the sensor can be monitored on a scanner.

- Watch the scanner while the engine is running.

- The O2 voltage should move to nearly 1 volt then drop back to close to zero volt.

- Immediately after it drops, the voltage signal should move back up. This immediate cycling is an important function of an O2 sensor.

- If the response is slow, the sensor is lazy and should be replaced. With the engine at about 2,500 rpm, the O2 sensor should cycle from high to low ten to forty times in 10 seconds.

- The voltage readings shown on the scanner are also an indicator of how well the sensor works.

- When testing the O2 sensor, make sure the sensor is heated and the system is in closed loop.

Testing With A Lab Scope  Correct way to connect a lab scope to an oxygen sensor. Correct way to connect a lab scope to an oxygen sensor.- A faulty O2 sensor can cause many different types of problems.

- For example, it can cause excessively high HC and CO emissions and all sorts of driveability problems.

- Most computer systems monitor the activity of the O2 sensor and store a code when the sensor's output is not within the desired range.

- Again, the normal range is between 0 and 1 volt and the sensor should constantly toggle from close to 0.2 to 0.8 volt, then back to 0.2.

A good O2 sensor trace. Courtesy of Progressive Diagnostics - WaveFile AutoPro. A good O2 sensor trace. Courtesy of Progressive Diagnostics - WaveFile AutoPro.- If the range that the sensor toggles in is within the specifications, the computer will think everything is normal and respond accordingly. This, however, does not mean the sensor is working properly.

- The voltage signal from an O2 sensor should have two to three cross counts with the engine without a load at 2,000 rpm. A cross count of an O2 sensor is the number of times the waveform moves from a high voltage and back to that voltage.

O2 sensor signal cross counts. Courtesy of OTC Tool and Equipment, Division of SPX Corporation. O2 sensor signal cross counts. Courtesy of OTC Tool and Equipment, Division of SPX Corporation.- If the sensor's voltage toggles between zero volt and 500 millivolts, it is toggling within its normal range but it is not operating normally. It biased low or lean. As a result, the computer will be constantly adding fuel to try to reach the upper limit of the sensor. Something is causing the sensor to be biased lean. If the toggling only occurs at the higher limits of the voltage range, the sensor is biased rich. In either case, the computer does not have true control of the air/fuel mixture because of the faulty O2 signals.

- The O2 can be biased rich or lean, not work at all, or work too slowly to ensure good emissions and fuel economy.

- To test the O2 sensor for all of these concerns, use a lab scope. Begin by allowing the engine and O2 sensor to warm up.

- Insert the hose of a propane enrichment tool into the power brake booster vacuum hose or simply install it into the nozzle of the air cleaner assembly.

- This will drive the mixture rich. Most good O2 sensors will produce almost 1 volt when driven full rich. The typical specification is at least 800 millivolts.

- Connect the lab scope to the sensor and a good ground.

- Set the scope to display the trace at 200 millivolts per division and 500 milliseconds per division.

- Inject some propane into the air cleaner assembly.

- Observe the O2 signal's trace. The O2 sensor should show over 800 millivolts. If the voltage doesn't go high, the O2 sensor is bad and should be replaced.

- Now, remove the propane bottle and cause a vacuum leak by pulling off an intake vacuum hose.

- Watch the scope to see how the O2 sensor reacts.

- It should drop to under 175 millivolts. If it doesn't, replace the sensor.

- These tests check the O2 sensor, not the system, therefore they are reliable O2 sensor checks.

- Also keep in mind that on an air pump-equipped car, it's a good idea to disable the air pump before doing this test. Unwanted air may bias the results.

- Observing the trace of an O2 sensor can also help in the diagnosis of other engine performance problems.

O2 sensor signal caused by an ignition problem. Courtesy of Progressive Diagnostics - WaveFile AutoPro. O2 sensor signal caused by an ignition problem. Courtesy of Progressive Diagnostics - WaveFile AutoPro.

The above figure shows how ignition problems affect the signal from the O2 sensor. Keep in mind that during complete combustion, nearly all of the oxygen in the combustion chamber is combined with the fuel. This means there will be little O2 in the exhaust of a very efficient engine. As combustion becomes more incomplete, the levels of oxygen increase. Ignition problems cause incomplete combustion and there is much oxygen in the exhaust. This is also true of lean mixtures, over-advanced ignition timing, or anything else that causes incomplete combustion.

When the mixture is rich, combustion has a better chance of being complete. Therefore, the oxygen levels in the exhaust decrease. The O2 sensor output will respond to the low oxygen with a high voltage signal. O2 sensor signal caused by defective fuel injector. Reproduced with permission from Fluke Corporation. O2 sensor signal caused by defective fuel injector. Reproduced with permission from Fluke Corporation.

Remember that the PCM will always try to do the opposite of what it receives from the O2 sensor. When the O2 shows lean, the PCM goes rich, and vice versa. When a lean exhaust signal is not caused by an air/fuel problem, the PCM does not know what the true cause is and will enrich the mixture in response to the signal. This may make the engine run worse than it did.

*********************************

Exact specs for your exact car and OE part could be all different,

T

(This post was edited by Tom Greenleaf on Oct 27, 2014, 7:23 AM)

|

|

|  |

|

Discretesignals

Ultimate Carjunky

/ Moderator

Oct 28, 2014, 6:08 PM

Post #10 of 10

(8242 views)

|

|

Re: oxygen sensor 2006 cobalt

|

Sign In

|

|

What is the trouble code number?

You should have one O2 sensor screwed into the exhaust manifold before the flange. Then you should have another O2 sensor after the converter. If the pipe on your new converter has a hole before the cat, you need to screw a cap into the hole. You sure there wasn't a cap in the box your new cat came in?

You need to have a sensor after the converter or else you'll get a P0420 code.

Since we volunteer our time and knowledge, we ask for you to please follow up when a problem is resolved.

(This post was edited by Discretesignals on Oct 28, 2014, 6:39 PM)

|

|

|  |

|

oxygen sensor 2006 cobalt

oxygen sensor 2006 cobalt

Use a wiring diagram to identify the terminals on a heated oxygen sensor. Courtesy of American Honda Motor Co., Inc.WARNING An oxygen sensor must be tested with a digital voltmeter. If an analog meter is used for this purpose, the sensor may be damaged.

Use a wiring diagram to identify the terminals on a heated oxygen sensor. Courtesy of American Honda Motor Co., Inc.WARNING An oxygen sensor must be tested with a digital voltmeter. If an analog meter is used for this purpose, the sensor may be damaged.  Correct way to connect a lab scope to an oxygen sensor.

Correct way to connect a lab scope to an oxygen sensor. A good O2 sensor trace. Courtesy of Progressive Diagnostics - WaveFile AutoPro.

A good O2 sensor trace. Courtesy of Progressive Diagnostics - WaveFile AutoPro. O2 sensor signal cross counts. Courtesy of OTC Tool and Equipment, Division of SPX Corporation.

O2 sensor signal cross counts. Courtesy of OTC Tool and Equipment, Division of SPX Corporation. O2 sensor signal caused by an ignition problem. Courtesy of Progressive Diagnostics - WaveFile AutoPro.

O2 sensor signal caused by an ignition problem. Courtesy of Progressive Diagnostics - WaveFile AutoPro.  O2 sensor signal caused by defective fuel injector. Reproduced with permission from Fluke Corporation.

O2 sensor signal caused by defective fuel injector. Reproduced with permission from Fluke Corporation.