|

|

Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

|

|

|  |

|

rebar

User

Jun 28, 2015, 9:02 AM

Post #1 of 31

(2470 views)

|

|

Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

1995

Ford

E350 van

5.9 cummins 5 speed

285,000 miles

Hello, New here..

Iv been trying to get my ac system blowing colder and harder. I found a plugged O-tube, flushed everything with lacquer thinner except the compressor and its hoses. Replaced the accumulator and blower, did triple evac, added 7oz of supercool pag 46 and 134a by weight instead of lowside pressure.

It performed better, 49 degree vent air, for about a half hour and then my clutch started slipping and got hot. It ruined the clutch , bearing and coil. The compressor is still holding the charge and turns nicely, but it got hot as well.

So now Im trying to decide if I should replace the compressor , or only the coil and clutch..

What I'm wondering about, is the reliability and quality of import compressors since no one builds anything in the US anymore! Don't get me started..

And second, did ford build the compressor in my 95? I'm only guessing it's original since I'm not the first owner. But I'm wondering if its American made, and I'm setting up myself for failure buying a import?.

Thanks

(This post was edited by rebar on Jun 28, 2015, 9:04 AM)

|

|

|  |

|

Discretesignals

Ultimate Carjunky

/ Moderator

Jun 28, 2015, 10:43 AM

Post #2 of 31

(2455 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Have never seen a 5.9 cummings in a ford van before. Sounds interesting.

What was in the orifice tube? Metal powder and shavings?

If so, you should read this:

http://autoforums.carjunky.com/...SOR_FAILURE_P116082/

Definitely would recommend replacing the whole compressor.

Your really not going to find an American company that makes compressors anymore. Most are outsourced. Compressor works used to be made and remanned in the US, but SMP bought them out. Honestly haven't had much trouble with the new import compressors. Denso and Motorcraft make really nice units. The main key is how you service and repair the system that will determine the life of the compressor.

Since we volunteer our time and knowledge, we ask for you to please follow up when a problem is resolved.

(This post was edited by Discretesignals on Jun 28, 2015, 10:51 AM)

|

|

|  |

|

rebar

User

Jun 28, 2015, 2:38 PM

Post #3 of 31

(2445 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Nothing metallic was on the O tube. It was plugged with hard black corrosion I hope. I was running 38/260 before I removed it.

After a flush , new accumulator, o tube, blower and 7 oz oil, it was running 25/150 with the factory 44 oz of 134a. So I added 2 additional oz to get 34/210

After good operation in the driveway I hit the interstate and had 49 vent air.. I pulled into town and the clutch smoked. First I figured I locked the compressor, but turns out the air gap probably allowed it to slip, or the coil finally failed. Either way it got very hot and I wonder if I coked the oil or refrigerant.

So Denso and Motorcraft are the best.. Thanks for your input.

Are there any extra's you would add to your new ac system if you were building from new? Iv read about additional dryer/filters, R12 Industrial refrigerants,Enviro-Safe ProDry etc?

Thanks! The cummins runs real well. Iv got a kingpin front and all the gear. But just not enough time or garage head room.

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jun 28, 2015, 4:11 PM

Post #4 of 31

(2437 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

You shouldn't be adding extra refrigerant to get the pressures you think you should have. You charge the system to the required weight and then you analyze the system from the pressures. There are numerous things that will make those pressures vary dramatically including but not limited to blower speed, ambient temperature, condenser condition, cooling fan efficiency and restrictions in the system.

You are overcharged now and probably should evacuate and recharge and start over. I would really question what plugged that tube up also. That isn't a natural occurrence. Something plugged it up and that something is likely still there. If it isn't pieces of the compressor, it could be sealer.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jun 29, 2015, 3:13 PM

Post #6 of 31

(2417 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Are you sure about that? Clutches usually don't simply smoke for no reason. It's usually due to something happening inside the compressor whether it be high pressure or just binding up for whatever reason.

I do a lot of AC work and I NEVER change just a clutch.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

(This post was edited by Hammer Time on Jun 29, 2015, 3:14 PM)

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jun 29, 2015, 7:00 PM

Post #8 of 31

(2409 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Sounds like you've got it covered. What's the bypass pulley for?

I'd make sure the cooling fan is pulling plenty of air as that is the most common compressor killer. That and overcharging.

I wouldn't be too concerned about the hoses. Any kind of flush will get them clean.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

(This post was edited by Hammer Time on Jun 29, 2015, 7:01 PM)

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jun 30, 2015, 5:23 AM

Post #10 of 31

(2393 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Quick comment on that you don't have a means to move lacquer thinner thru fast? You would need a LOT of compressed air by volume at some pressure. Don't mess up the job leaving thinner in this system..........

T

|

|

|  |

|

rebar

User

Jun 30, 2015, 11:38 AM

Post #11 of 31

(2386 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Quick comment on that you don't have a means to move lacquer thinner thru fast? You would need a LOT of compressed air by volume at some pressure. Don't mess up the job leaving thinner in this system..........

T

Iv got plenty of dry clean shop air. I initially used one of the car parts store aerosol can flush, only to find out I needed lacquer thinner anyway to rinse the mineral spirits. I'm still unclear the best method.

I have my doubts I removed all the deposits from my tube in fin condensor. But also reluctant buying new condensor with the micro passages..

Just now removed. There are still a few black specks on the screen, which were also seen on my condensor flush. I agree, some passages could be blocked. And I remember when I was blowing it out. I had it blowing, and then the sound, or amount of air coming out changed. I blew it off, blaming my poor hearing, but now think some debris must have moved around to cause that.

(This post was edited by rebar on Jun 30, 2015, 12:52 PM)

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jun 30, 2015, 12:34 PM

Post #12 of 31

(2382 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

No, replace the condenser. You can't flush most of them. They are a bypass design where one manifold feeds all the tubes. You can have 90% blockage and still blow through the couple that aren't blocked and think it's clear. Unless it is a serpentine design, then you could flush it but it would take a lot of chemical and air pressure.

Don't even mess with the evaporator. That will be fine. You can't blow everything out of it anyway.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

(This post was edited by Hammer Time on Jun 30, 2015, 12:35 PM)

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jun 30, 2015, 3:19 PM

Post #14 of 31

(2369 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

I thought all vacuum pump oil was the same. My supplier only carries one choice.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jun 30, 2015, 3:28 PM

Post #15 of 31

(2367 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

I want to know the answer(s) that may come with that question too. Have seen the warnings on assorted things like that to use "only XYZ" (their own) oils and you don't always know if unique or what.

To me most are an engine of sorts some quite like an engine. Compressors for shop and vacuum pumps just opposite in some ways. Have a Dayton now old with a sight glass for oil and at the risk of wrecking it put in synthetic engine oil Been fine for ages, runs smooth and never fails to achieve max vacuum which is the game however you get there.

Put same in an air compressor and it too is old and works perfectly - very much a piston thing on top.

If left to a default answer I'd have to say use only what it says. To be the Devil's advocate windshield washer fluid if not now once said only use stuff made by the manufacturer! What!!

Another expensive hydraulic thing that attaches to my own truck says use only there stuff for some unreal price - did and later to find out it's synthetic ATF - arseholes -and I went out of my way to pay tons more for the same crap.

Interested in what others suggest and can't say for YOUR specific pump. Guess it's proven (if only by me) that some of it is bull but also know some isn't,

T

|

|

|  |

|

rebar

User

Jun 30, 2015, 4:56 PM

Post #16 of 31

(2361 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

According to link deleted ............ not allowed

Its mineral oil.

NTE783932

(This post was edited by Hammer Time on Jul 1, 2015, 2:11 AM)

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jul 1, 2015, 12:46 AM

Post #17 of 31

(2351 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Thanks rebar: Link may have to go but I'll post a question and response from it..........

Q.Don't mean to hijack the post, But could vacuum pump oil be used in an air compressor? I'm thinking JB Black Gold might be better oil than Sears sells for air compressors. Just wondering out loud. John

---------------------------------------------------------

A.Yes. Compressor oil is usually just mineral oil. In most reciprocating compressors, you could probably use just about any oil that doesn't foam and isn't too viscous.

******************************************

This is still under advisement to use what a specific product/item called for as I personally couldn't speak for ALL of the "things" out there.

The key to many things is range of temperatures lube will work + lack of foaming. Now throw in does it need to be "rubber friendly" and or "hygroscopic" (moisture absorbing such as PAG oils and even brake fluid?)

%%%%%%%%%%%%%%%

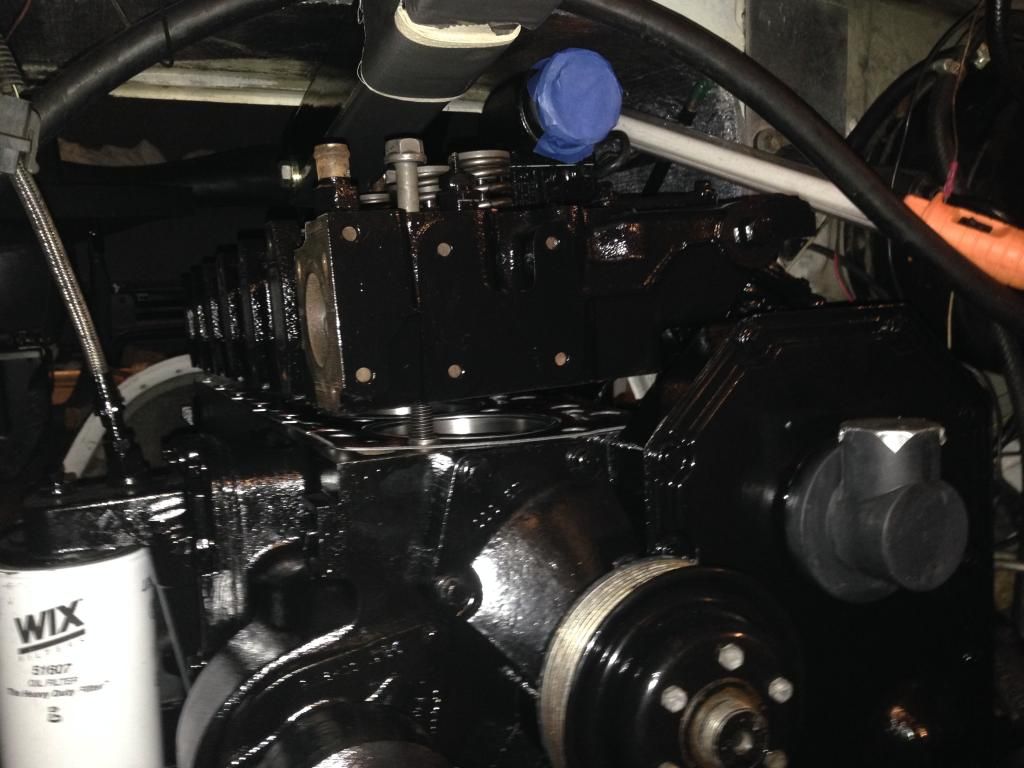

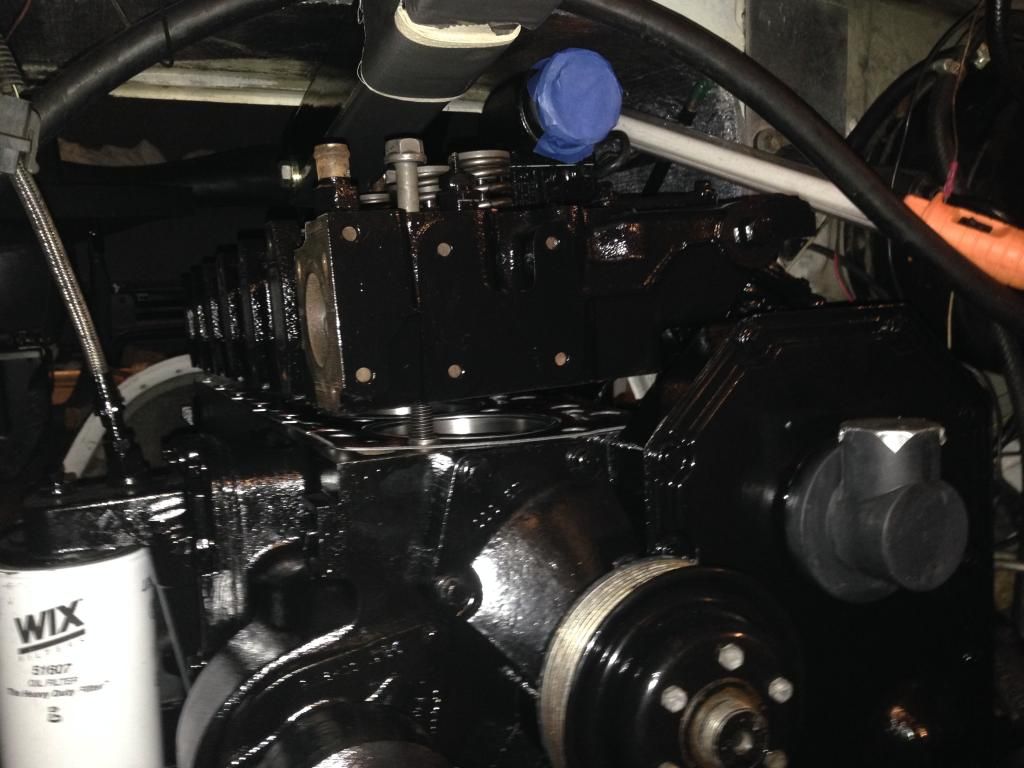

To your van and the subject line alone: Your pic is enough to toss that compressor as part of the fix total fix. I suggest when possible to go completely NEW w clutch NOT rebuilt. Rebuilt anything makes me wonder what the heck the one that was rebuilt was like when you really can't know if it was fit to rebuild or not for sure. Did you get one from a wrecked vehicle or one from some wear out or even an intermittent fault? I totally distrust shaft seals being replaced. Can easily test fine on a bench and NG when in the real world use.

Not compressors (automotive) but other assorted things I pay the 'core' charge if a common item and redo that one myself later depending on the failure, cost of rebuild parts factored in also.

Good luck with this job. You've said you really need to avoid "down" time with this vehicle so all that more important to get it right the first time. A/C if job fails so easily puts you right back just as bad off as the original problem or worse! Not a great place to "save a buck" now area of things you might fix in general,

Tom

|

|

|  |

|

rebar

User

Jul 1, 2015, 4:40 AM

Post #18 of 31

(2339 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Woops, my bad..

Another thread I read people questioned if baby oil was suitable for vacuum pumps.

But at $7 quart for NTE783932 you cant go wrong..

And on the topic of oil.. Last time, I pulled triple evac and put 4 oz PAG 46 in the accumulator and 3 in the high side since I didnt take the hoses off the compressor but did drain it.. In hind site, that probably wasn't the best approach.

Should I put 3 oz in the evap, 1 oz in the condensor inlet, and 3 oz in the compressor before evac?

I like to leave the new accumulator closed until the very last step after Iv pulled vacuum on the rest of the system and filled a little over atmospheric with 134a.

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jul 1, 2015, 4:57 AM

Post #19 of 31

(2336 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

I would put nothing in the evaporator.

You really need to have some idea how much of the previous oil is still in the system.

Depending on what the total capacity of the system is, on average I put about 4-5 ounces in the compressor and I add another 2 through vacuum during charging.

You also want to spin that compressor by hand about 10 revolutions before starting the engine to purge all that liquid from the chambers.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jul 1, 2015, 5:12 AM

Post #21 of 31

(2331 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Quote">>I like to leave the new accumulator closed until the very last step after Iv pulled vacuum on the rest of the system and filled a little over atmospheric with 134a.<<"

What do you mean by that? Fine if you can plug off parts of the system to vacuum and yes accumulator should have desiccant in it you don't want to expose to air for long at all.

Full vacuum is full vacuum w only the slightest variation if close or at sea level is 29.92Hg. Know your altitude and if significant fractionally can deduct 1 Hg per 1,000 ft. of elevation. The idea is air and moisture out. Moisture can't exist in a vacuum as it will boil off.

Jury mostly still out on if you can get moisture back out of PAG oils or desiccant and partly concluded you could it you had it both in a vacuum and quite hot - not proven.

Just FYI if you missed it in any info. Air contains moisture (bad) plus doesn't condense at any reasonable pressure (1,000s of PSI) so of no use and a total screw up if mixed in with refrigerant results would be all kinds of erratic.

BABY OIL: I can't suggest that as it isn't rated for exactly what it is, what % pure or what else could be in it? So NO if there's any choice. A/C is just too costly to take chances with unknowns. Enough can go wrong without that,

T

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jul 1, 2015, 7:24 AM

Post #25 of 31

(2319 views)

|

|

Re: Is it cost effective replacing coil and clutch after they melt? Or total rebuild?

|

Sign In

|

|

Yes on that^^^^

Without knowing exact equipment you are using it can be hard to describe just how you can be close to 100% sure no air is in the vehicle's system.

Ex: I can use TWO sets of gauges attached one with low (blue hose) to vacuum the other to high (red) and vac the gauge sets as well. This with system already to go and has proven a well held vacuum. Now under vacuum can add (measure weight of refrigerant all along to at least an ounce) liquid or gas to high side watching low side set go into pressure not vacuum. That is about proof that air can't get into something under pressure.

Depending on your equipment and you have to know your own and what is pressure, vacuum, refrigerant or possible air at all times.

Spits of air seem to be expected by the vehicle makers so desiccant is used. It can only handle so much.

Unknown how much moisture expressed in PPMs will cause problems? I do know of systems ages old known from new that can perform as new with total attention to any work they might need along the way.

Do know that when system is ready to engage compressor no matter how that's accomplished it needs oil quickly only carried along at about the time it can blow cool air. IDK - bet a lot of quick failures are running a new compressor dry of oil taking too long to have charge proper or real close. High buck equipment can do that before you even allow a compressor to engage. Most folks wouldn't have that caliber of equipment.

As said, risks are high for things to get costly. Mistakes are #1 on the list,

T

|

|

|  |

| |  |

|